What’s New to SolidWorks 2019

With another year coming to a close a new and improved version of SolidWorks has been released, SolidWorks 2019. This new SolidWorks version is full of powerful new modeling tools and various other updates to help bring design and manufacturing closer together. These updates and features cover all aspects of SolidWorks including, Assemblies, Routing, Drawings, PDM, Plastics, Simulation, Visualize, and much more.

Figure 1 – Photo from SolidWorks Event

Updates to Assemblies, Parts, and Drawing Features

Making large assemblies both run and load faster has been a goal of Dassault’s almost every year. With assemblies growing more and more complex the need for better assembly performance is long overdue. SolidWorks 2019 has done a great deal to fix this issue by taking computing stress off the CPU and sharing it with the computer’s graphics card. This allows for quick and seamless assembly manipulation. 3D textures can now be applied to 3D models. This process used to take many features and a large chunk of time to add in a simple feature like knurling. Now all the is needed is textural appearance and the use of the new “3D Texture” tool to create complex surface geometries quickly and easily. As for drawings, SolidWorks 2019 allows cell border thicknesses to be changed individually for each cell. Opening drawing documents also will now prompt a progress indication to show both number of components and time taken to open the document.

Updates to SolidWorks Visualize

Setting up a render to achieve picture perfect accuracy can take a long time, and even longer if your session ends unexpectedly and all that work needs to be redone. SolidWorks 2019 offers a new auto-recover option inside visualize to help prevent lost work if the session is closed unexpectedly. Along with the auto-recovery features comes the denoiser option to visualize to help produce faster and more accurate renders. The denoiser is a simple checkbox option to be selected, it allows for fewer passes and faster render time using a post processing technique to filter out unfinished images.

Updates to SolidWorks Plastics

As for plastic part and mold creation some changes do come in 2019 as well. With the new SolidWorks version comes the ability to add geometry based boundary conditions to models. This update allows for features on the model to be assigned as injection locations, control valve locations, and temperature boundary conditions. An enhanced algorithm has been added to allow more accurate and complicated cooling channels to be formed from sketch lines. This new algorithm gives cooling channels an overall better look and greater precision. Mesh enhancements have also been made to SolidWorks plastics. SolidWorks 2019 allows a mesh to be created before a part file has been saved off. Mesh can also be assigned faces, edges, and vertices before creation. Information about the mesh statistics can now also be pulled in 2019 allowing you to view any bad elements about the mesh and much more.

Updates to SolidWorks Routing

SolidWorks routing has now been updated to allow the creation of partial or fixed length coverings. A “fixed length covering” tool has been added in to allow various locations and segments of the routing to have custom covers. Improvements have also been made to the Routing Library Manager. These updates to the library include displaying only essential tabs that are needed for routing creation, along with increased response speeds when switching through tabs.

Updates to SolidWorks PDM

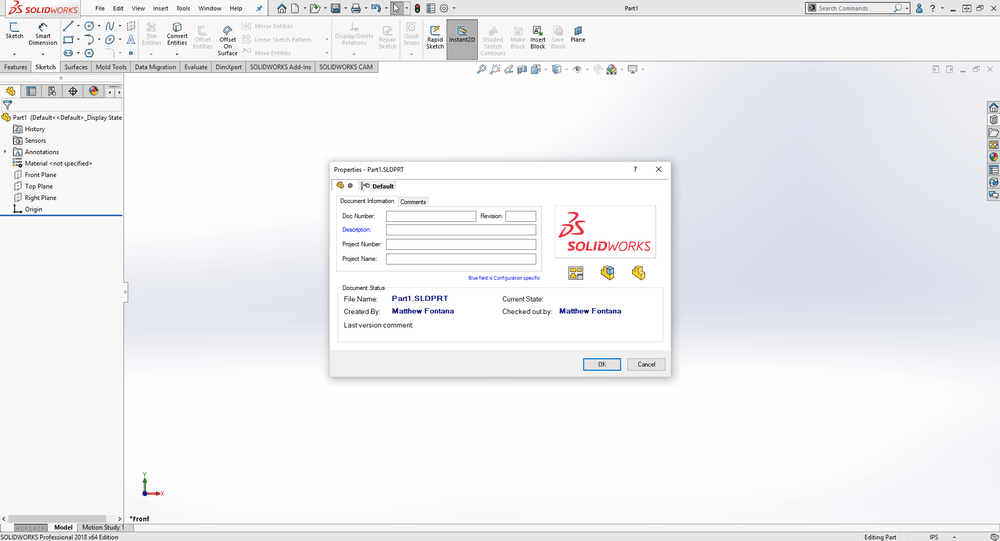

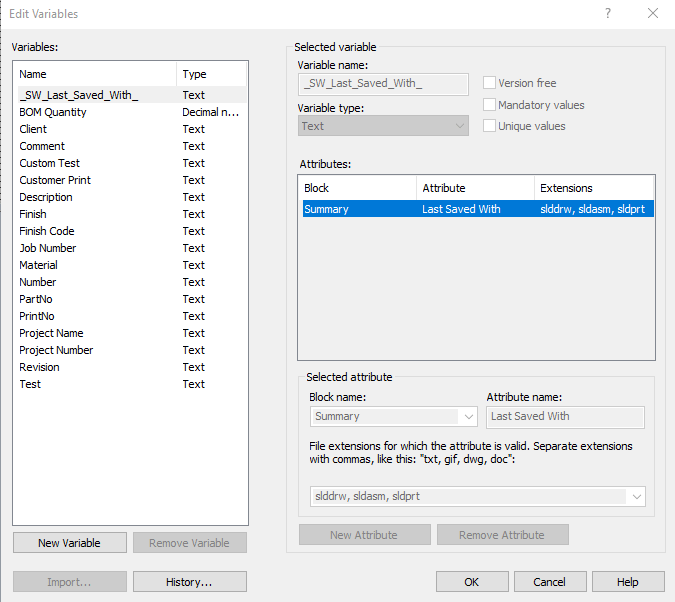

This new version of SolidWorks comes with a long list of much needed updates to PDM. First, performance has been improved for handling large assemblies and complex reference structures. This allows for assemblies with a large number of components to be checked in quickly and easily. Conditional notifications have been added to allow predefined conditions to be set and send transition notifications to users and groups. This also allows notifications to be sent dynamically to users based on variables found on the data cards.

Conclusion

SolidWorks 2019 is bringing a multitude of updates and features to help users bridge the gap between design and manufacturing. It does not seem like it will be long before every tool you need to go from design to manufacture will be available to you in a single program. What was talked about in this blog was only the beginning to some of the updates in SolidWorks 2019. If you would like to dive deeper into some of these new updates or find others that were not talked about visit the SolidWorks site here: http://help.solidworks.com/2019/English/WhatsNew/c_welcome_solidworks_2019.htm?id=9e4cebd3c875458d9bcb529e16b720ab#Pg0

Figure 2 – Photo from SolidWorks Event 2