The proper formating of the hole wizard feature will allow the user to easily control and change any number of holes at once. This is good practice for the modeling efficiency will be much faster and in the future, adding fasteners will be much smoother as the hole wizard can be used to pattern features.

Hole Wizard Introduction

Hole wizard is a useful tool in SolidWorks used to control the features and properties of multiple holes at once. The Hole Wizard Feature allows you to create a variety of different types of hole cutouts for area and function specific applications.

![]()

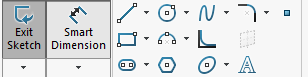

Figure 1: Command Manager Icon

The hole option types are as follows: counterbore, countersink, drill, straight tapped, tapered tap and legacy. Among each of those options, Hole Wizard also allows you to generate counterbore, countersink, and traditional slots. The counterbored and countersink holes add a flat-bottomed hole cut and angled lead on the top side of the hole which is often used to sit fasteners flush with the surface of the part.

The drilled hole type allows access to various drill sizes and varieties, such as a dowel, fractional, helicoil, number/letter sizing, screw clearances, and finally regular or pipe tapped drills. Straight tapped holes add a constant threading along the hole direction; while tapered tapped holes add the varying hole and thread size with respect to the hole depth. Finally, the legacy hole is customizable hole feature that allows you to input various sizing to construct a hole specific to your needs.

Operating the Hole Wizard

First selecting the Hole Wizard icon in the command manager shown in Figure 1, the feature manager will appear on the screen and the Type tab will be automatically preselected.

Figure 2: Hole Wizard Feature Manager

The Type tab is used to select the type of hole you intend to create. Additionally, this tab allows you to specify other parameters involving the hole such as the standard, the size and depth of the intended hole, and other custom options specific to each hole type.

After configuring the properties the specific holes, the Positions tab is used to generate a sketch which defines a point or set of points for each hole location. Like any sketch, a surface or reference plane must first be selected to start your sketch. This can be done by either preselecting before entering the feature or in the feature when in the positions tab.

Figure 3: Hole Position Interface

With each point that you add in the sketch, a hole preview will appear which better shows your hole location and area size that the hole will take up. After the hole positions are placed and the hole previews look correct, based on your specified hole type, click the green check mark to finish the wizard.

Tips & Tricks

While you may be able to use an extruded cut for simple holes (especially clearance holes), our engineers and designers here at Perception Engineering, among many others, highly recommend that you use hole wizard for all hole type applications. Using hole wizard features will allow you to drive feature-based patterns that can save a lot of time in the following stages of the project. An excellent example of this is when adding fasteners to an assembly. Here, the Pattern Driven Component Pattern can be used with hole wizard to mate fasteners into their corresponding hole locations with ease. Additionally, make sure to utilize all the sketch related tools at your disposal when placing your hole locations especially: mirroring, centerlines, and patterns.

That’s all for now! You now know the basics to Hole-Wizard. If you like the content or have questions, signup for our email list to stay in the loop for solutions or weekly content.

Written By: