Custom Drawing Template

A drawing template is one of the main components to any assembly or part drawing. A drawing template allows you to convey all information about a part or assembly in a clean and organized manner. The key features of a drawing template are simplicity and clarity. This blog will demonstrate how to make a simple custom drawing template in SolidWorks!

Opening A Drawing Sheet

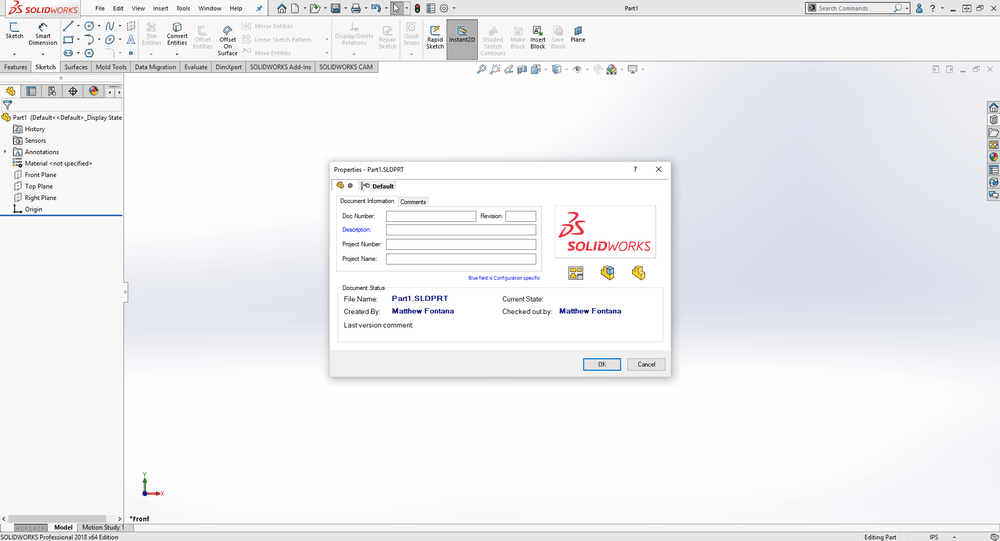

To create a custom drawing template, a blank template is needed to start the creation. SolidWorks offers multiple different sizes and shapes of pre-made drawing templates inside the programs files. One of these pre-made templates will be open and altered to make it blank. Click on the new document command on the toolbar at the top of the screen or under the file drop-down menu. After trying to open a new file, a pop-up box will appear. Under the novice setting tab, there will be three options: start a part, assembly, or a drawing. Choose the create new drawing option. Another pop-up window will appear with a list of A-E drawing templates. These are SolidWorks default templates. Any size can be chosen but for this blog, the A(ANSI) Landscape template will be modified. An image of how to get to the custom SolidWorks templates is shown below in Figure 1.

Figure 1: SolidWorks custom template location

Clearing the Format

Once the pre-made template has been opened, the formatting needs to be cleared to be able to input a new custom template. In the feature manager on the left, there will be two features, these are “Annotations”, and “Sheet1”. Click the drop-down arrow next to sheet1 and another feature will appear called Sheet Format1. Right click on Sheet Format1 and select delete, the drawing template will then turn blank. An image of how to clear the format is shown in Figure 2.

Figure 2: Clearing the sheet format

Editing the new sheet

Now that the sheet has been cleared, a new format can be created on it. In the drawing, select the Sheet Format tab located on the toolbar near the top of the screen. Select the Edit Sheet Format command on this tool tab. After this command is selected the other two commands on this tab will become available to use. Now, select the Automatic Border command. Where to find these commands is shown in Figure 3.

Figure 3: Editing commands location

After the Automatic Border command is selected, the property manager will show a delete list selection box. Since the format is already cleared, this step is not needed. The blue arrow at the top right of the property manager can be clicked to move onto the next step in the command. After the blue arrow is clicked, the property manager will be filled with multiple different options on how to adjust the border that is being previewed on the drawing sheet. The zones, margins, line size, and borders can all be edited here. Once the desired sizes have been chosen, click the green check mark at the top of the property manager. There will now be a border around the drawing template. The Automatic Border property manager is shown in Figure 4.

Figure 4: Automatic Border property manager

Adding Sections

Now that the border is finished, some sections for information need to be added to help keep the template organized. To add in sections, they simply need to be sketched in. Go over to the sketch tab and select the line or rectangle command. Create some boxes and proportion them to the size and shape that is desired for the custom template. An example of the sections made for this blog is shown in Figure 5.

Figure 5: Example added sections

After the sections have been added in they need to be labeled. This can be done by placing annotations notes in each box. The Note command can be found under the annotation tab on the toolbar near the top of the screen. A note is placed in each box of the title block. This is done to give an input location for information about the drawing. Note size and shape can be adjusted by double-clicking on the note itself. An example of the layout for notes in a drawing template is shown in Figure 6 below.

Figure 6: Example section labels

Finishing Touches

Notice that there is still a large empty space inside title block area. Typically, in this space or one like it, a decal belonging to either the person or the company is placed to show ownership of the template. These pictures also help make the template look more aesthetically pleasing. For this blog example, the Perception Engineering logo will be added. To add a picture to the template the edit sheet format command must still be activated. If it is not, click on the command again. Go to tool on the toolbar at the very top of the screen and drop down the menu. Find the sketch tools menu and hit that drop-down menu as well. Under the sketch tools menu, there will be a sketch picture command. After clicking this command simply select the desired picture from its file locations and it will be placed onto the template. The picture can then be sized and edited in its property manager on the left-hand side. An example of this is shown in Figure 7.

Figure 7: Sketch picture example

Saving the New Template

Now that the new drawing template is complete, it must be saved! To save this as a template to be used all that is needed is to save the file as a drawing template (*.drwdot) file. After it has been saved as a drawing, the file locations need to be edited to pull the template. Click on the gear at the top of the screen and select file locations in the menu on the left side of the pop-up menu. Under the “show folder for” drop-down menu, select Document Templates. All that is left to do is select the folder that the drawing template was saved in and it can now be pulled to use as a template anytime! How to access the file locations is shown in Figure 8.

Figure 8: Editing the file locations

Final Thoughts

The purpose of a drawing template is to help with organization and presentation of a drawing and its information. A well-organized drawing template is a sure-fire way to portray professionalism when creating drawings. Even with just a simple template and title block such as the one shown in this blog, the look of a drawing can be increased as well as how easy it is to read and gather information.